Half & Fully Sheathed Ring Heaters

Application »

HS / FS ring elements owing to their convenient shape & sizes, adapt themselves readily to variety

of machines and appliances for which other type

of heaters are not suitable. They are being fitted

for heating platens, dies of presses. They are in use for melting of glue, wax, easily fusible metals

like leads, tin, solder, hot plates, popcorn machines, high speed packing machines, difussion pumps, kettles, large coffee percolators & wash boilers etc.

Construction »

Chrome steel sheath on one side and edges, other flat side is the bare refractory. Coiled electric resistant wire embedded inside. And steel terminal studs with nuts washers.

Advantage »

Being sheathed on one side only, It has very little residual heats and stands up to 650° C. Temperatute for its's surface area.

Available iN standard packing & contains two or ten pieces »

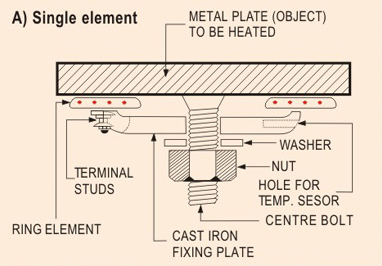

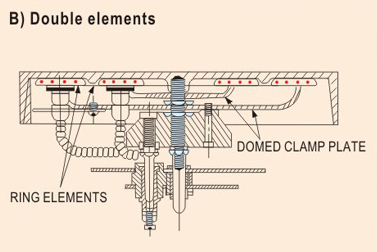

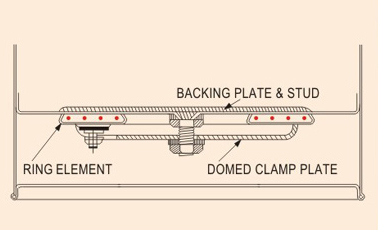

methods of mountaining HS / fs ring heaters »

| |

|

|

If the utensil is having thick buttom. The mounting of the element is very simple. A centre bolt & a concave fixing plate alone being necesasry, as shown. |

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

| |

|

|

If the utensil button is thin, we suggest to strength it by means of brass / SS backing plates which makes one piece with the fixing bolt mounted as shown. |

|

Standard Sixe & Capacities »

| |

Type |

Max Wattages

230 / 250 VOLTS |

Dimensions (in mm) |

|

| |

Ring Inside Dia. |

Ring Outside Dia. |

|

| |

Half Sheathed (HS) |

Fully Sheathed (HS) |

Half Sheathed (HS) |

Fully Sheathed (HS) |

|

| |

HS / FS - 1 |

350 |

27 |

25 |

88 |

90 |

|

| |

HS / FS - 2 |

400 |

50 |

48 |

100 |

102 |

|

| |

HS / FS - 3 |

500 |

50 |

48 |

111 |

112 |

|

| |

HS / FS - 4 |

1000 |

62 |

60 |

134 |

136 |

|

| |

HS / FS - 6 |

1250 |

90 |

88 |

160 |

161 |

|

| |

HS / FS - 7 |

1300 |

113 |

111 |

178 |

180 |

|

| |

HS / FS - 8 |

1600 |

129 |

126 |

201 |

203 |

|

| |

HS / FS - 9 |

17580 |

152 |

151 |

218 |

220 |

|

| |

HS / FS - 10 |

2000 |

225 |

223 |

300 |

302 |

|

- HS - 1 have 4BA thread terminals studs, and all other type are with 2BA threads studs.

- Heater is not recommended for direct immersion in liquid.

- Heater wuth different Wattage/Voltage can also be made.

- Theses Heatercan be used one inside the other in following manners.

| Types |

To Give Total Loading Of |

On A Utensil Dia |

| HS - 10 + HS - 9 & HS - 4 |

4750 Watts |

305 MM |

| HS - 9 + HS - 4 |

2750 Watts |

220 MM |

| HS - 8 + HS - 3 |

2100 Watts |

202 MM |

| HS - 7 + HS - 3 |

1800 Watts |

180 MM |

| HS - 6 + HS - 1 |

1600 Watts |

162 MM |

| This Combination is also available in Fully Sheathed (FS) Heaters |